In-line bottle wall thickness measurement system

Problem

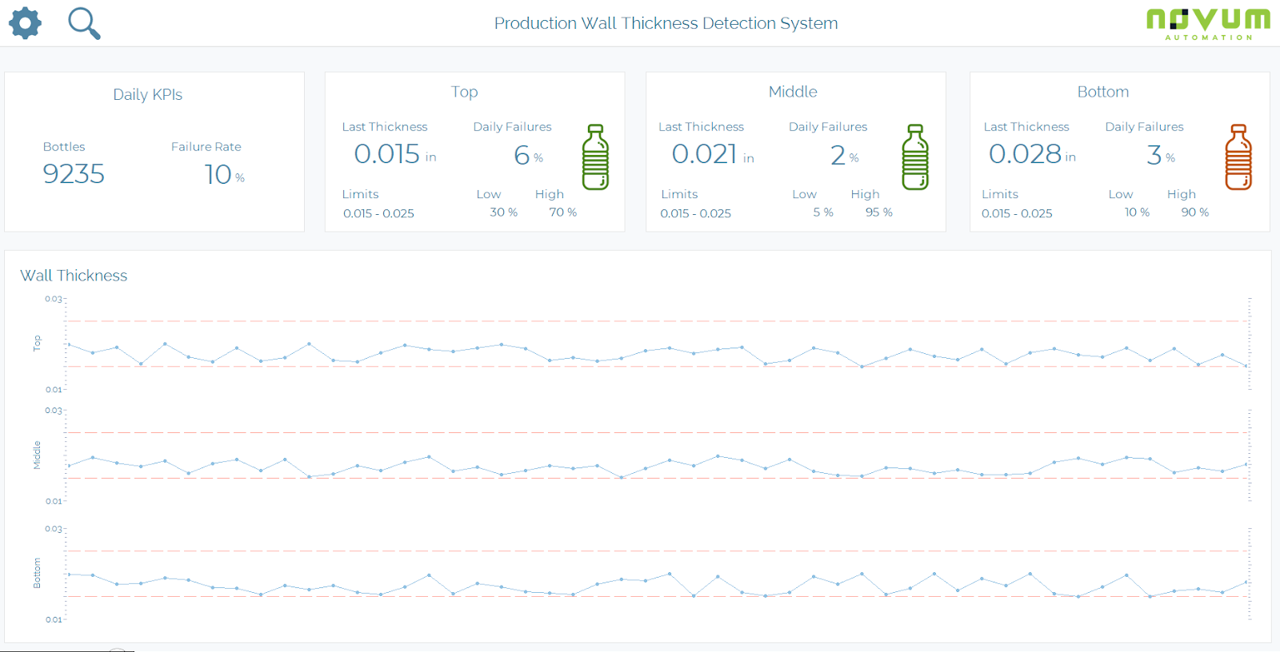

A high-volume plastic bottle manufacturing line required tight tolerances on bottle wall thickness at multiple locations. The customer was performing hourly manual audit checks on a sampling of bottles to minimize out-of-spec bottles being shipped to customer. The end-customer still received out-of-spec bottles, requiring shutdown of receiving until 100% inspection was performed.

Solution

Novum Automation designed, developed, tested, and commissioned a PROMEA in-line 100% non-contact wall thickness measurement system within 4 weeks of PO. Based on the provided system, the end customer allowed receiving of bottle shipments again.

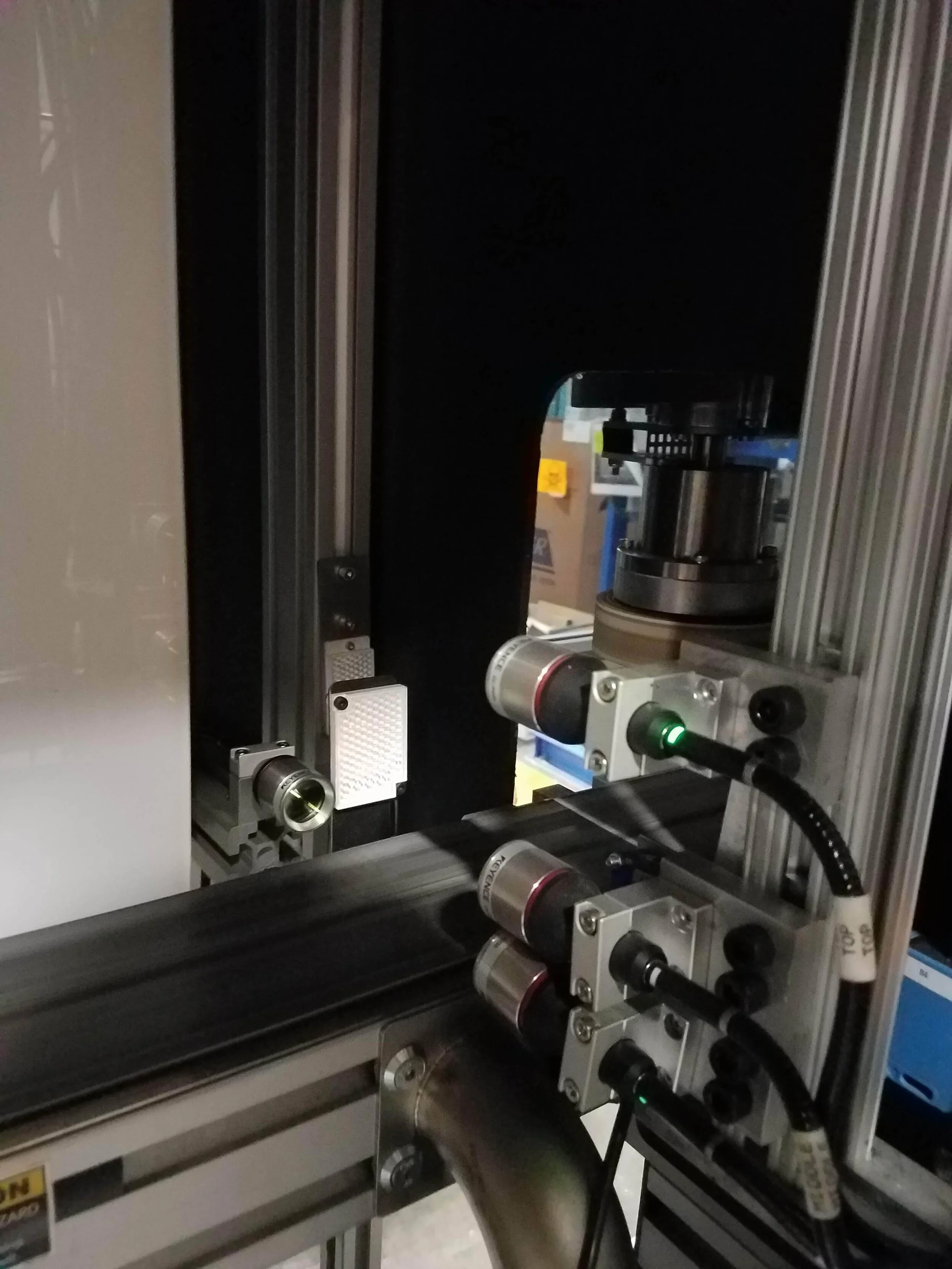

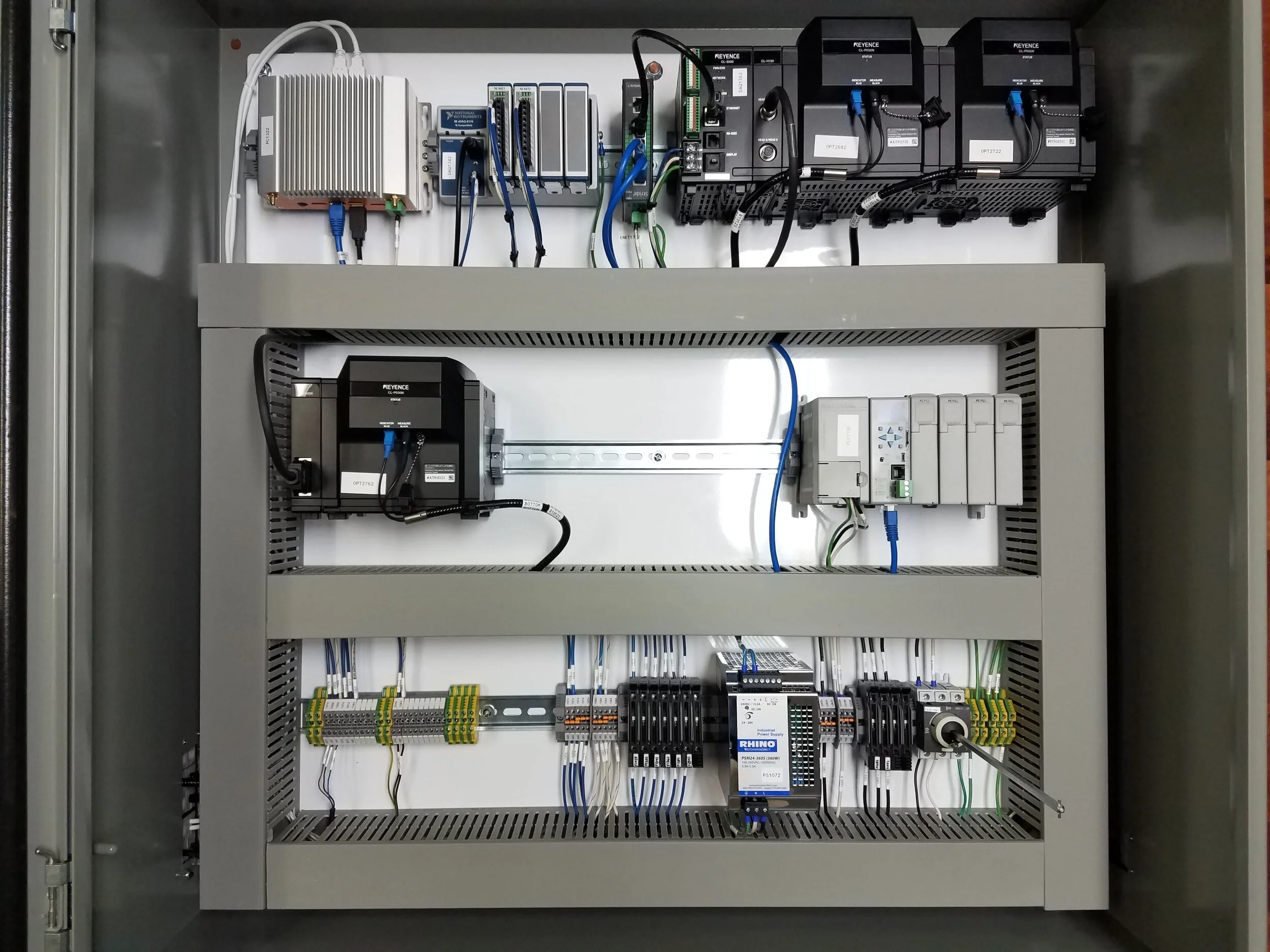

Utilized Keyence CL-3000 Controller & CL-P030 Measurement Head to capture precision wall thickness via non-contact measurement means (light refraction)

System was capable of measuring thickness on over 75,000 bottles/day at three critical wall thickness locations to a precision of +/-.0001 in.

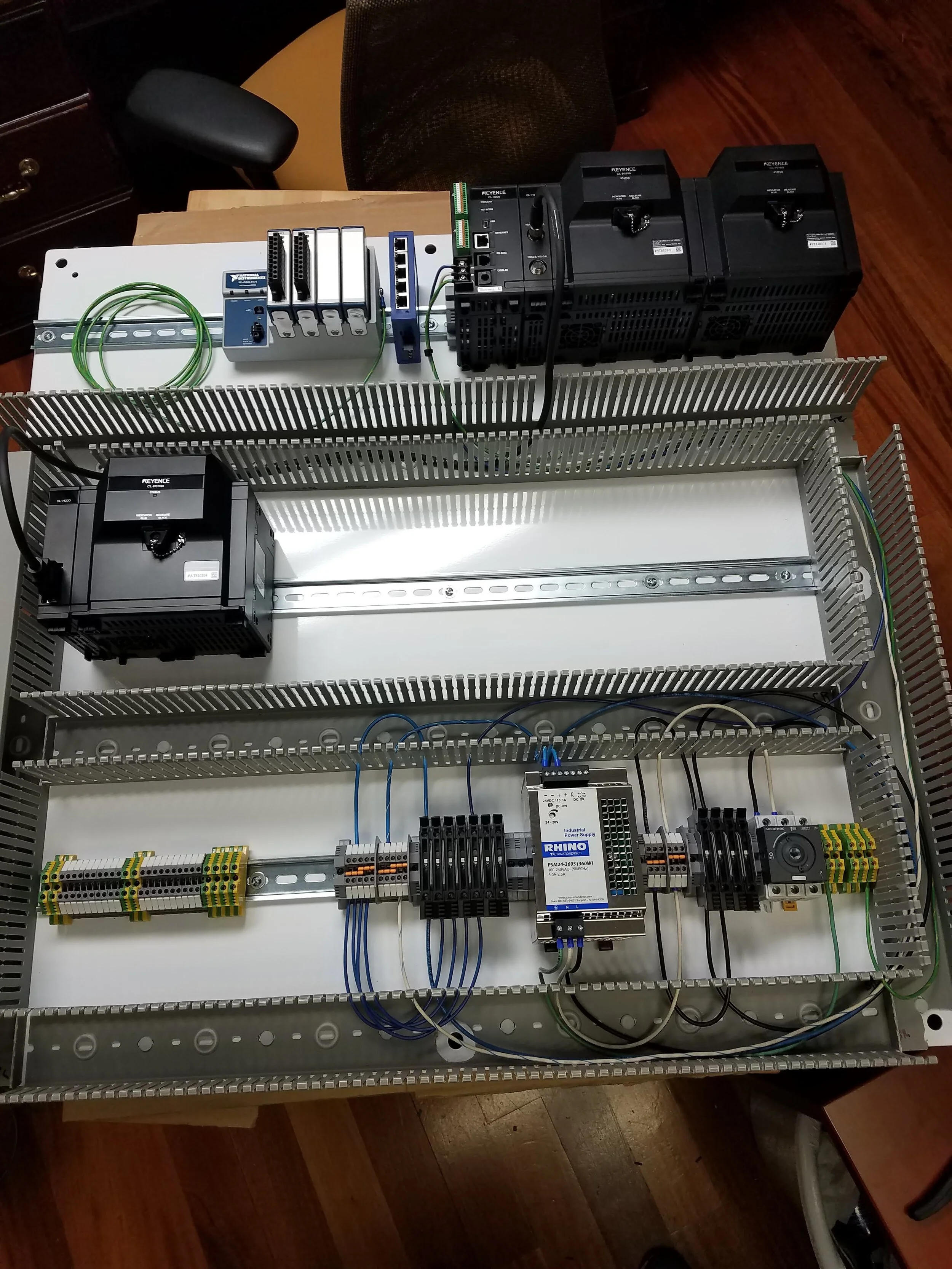

Programmed custom software using National Instruments’ LabVIEW IDE

Utilized Productivity2000 PLC for EthernetIP-Modbus TCP interim data transfer

Integrated pneumatic blow-off control that allowed for immediate removal of all out-of-spec bottles

Stand-alone system pushed data to AWS RDS MySQL Database for analysis via Tableau Business intelligence software

Only 1 day of installation required for mounting of sensors and system tuning

Based on Novum’s standard PROMEA product offering (with application-specific development)