Planetary gearbox end-of-line tester

Problem

Outsourced planetary gearbox acceptance required thorough inspection before shipment to confirm correct assembly and to detect manufacturing defects.

Solution

Within one month an intuitive, turn-key test system that was capable of detecting planetary gearbox assembly deficiencies was shipped globally.

Four test stations were built, capable of running independent, asynchronous operation

Test software was developed using National Instruments’ LabVIEW IDE with a user interface built primarily of icons to minimize language translation barriers

The control system utilized a brushless DC motor to rotate gearboxes continuously while monitoring for torque averages and torque spikes using high-speed precision current sensors on the motor power supply line

OnLogic NUC industrial PC was selected to run custom LabVIEW executable software

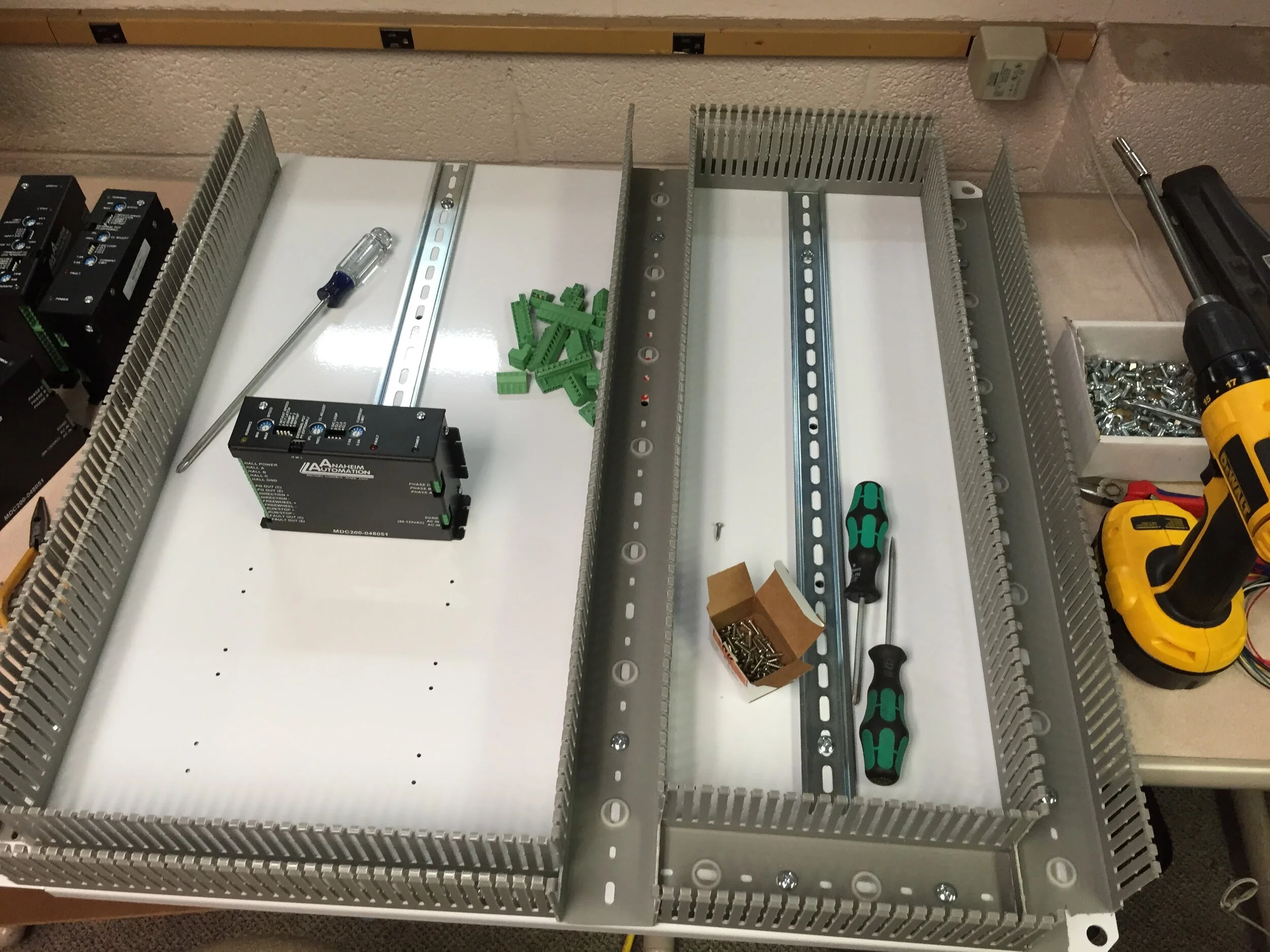

Quick-disconnect system components were utilized and compartmentalized for quick replacement to mitigate damage or failure during operation

All mechanical design, electrical wiring, LabVIEW programming, component assembly, and validation testing was performed within 4 weeks