Commercial clutch fan production testing

Problem

An automotive manufacturer’s 30-year-old end-of-line (EOL) clutch fan test system was becoming unreliable and costly to maintain. The test system uses 75 HP AC motor and heat chamber to apply controlled temperatures and verify engagement/disengagement of clutch at required speeds and temperatures. Controls utilized obsolete hardware with outdated electrical schematics. Custom LabVIEW test software was developed using poor programming techniques which produced unreliable and non-maintainable code.

Solution

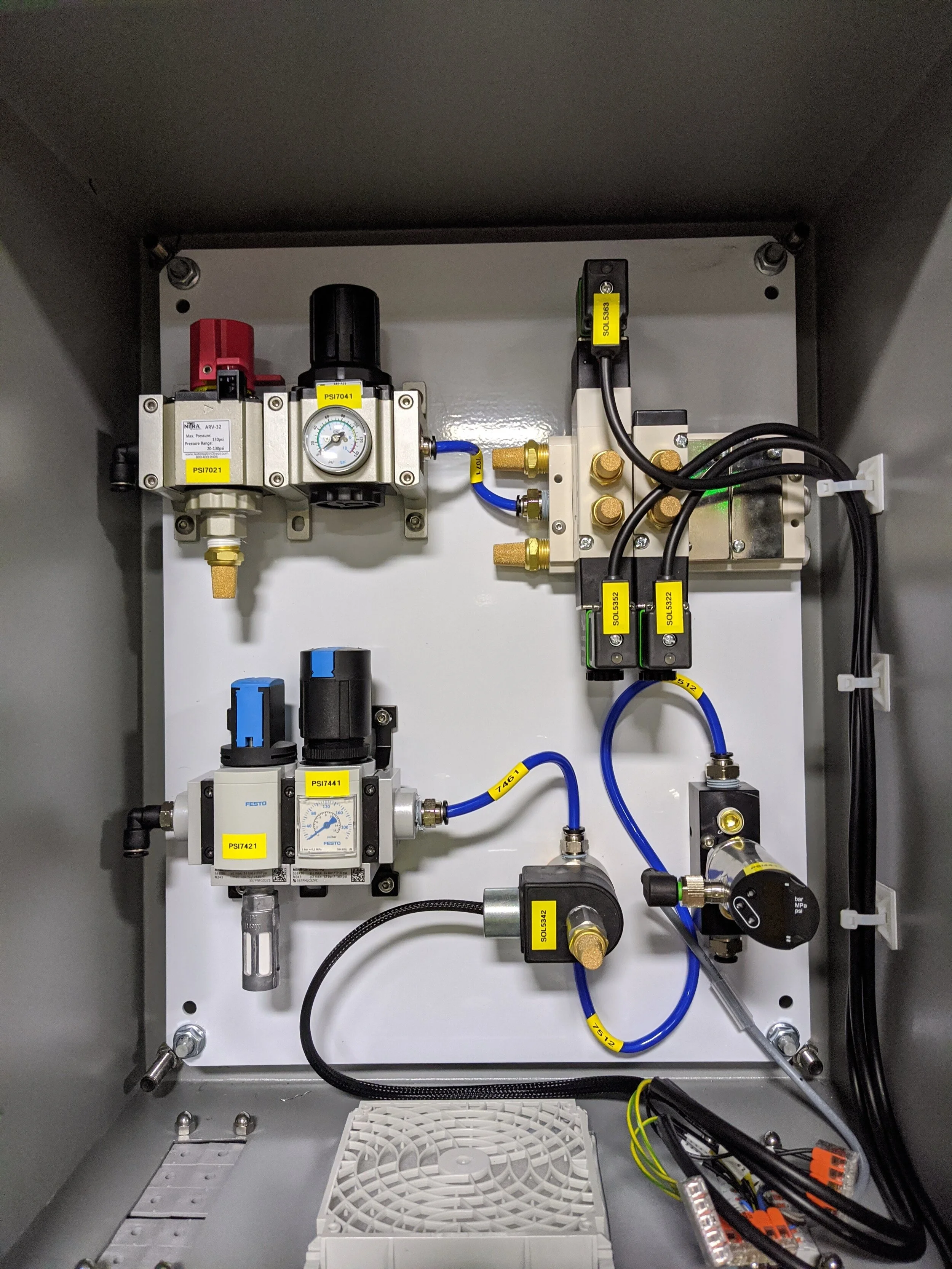

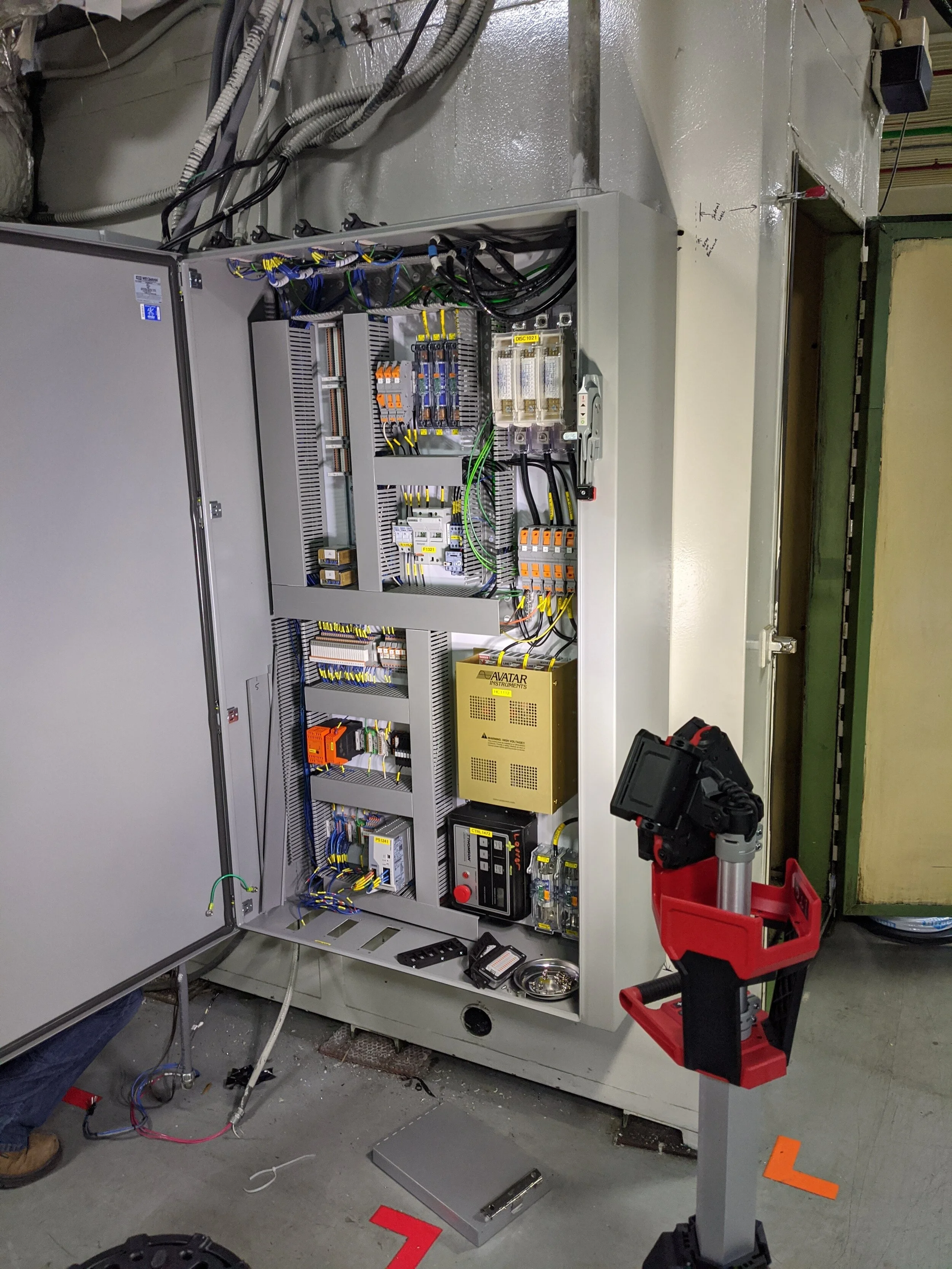

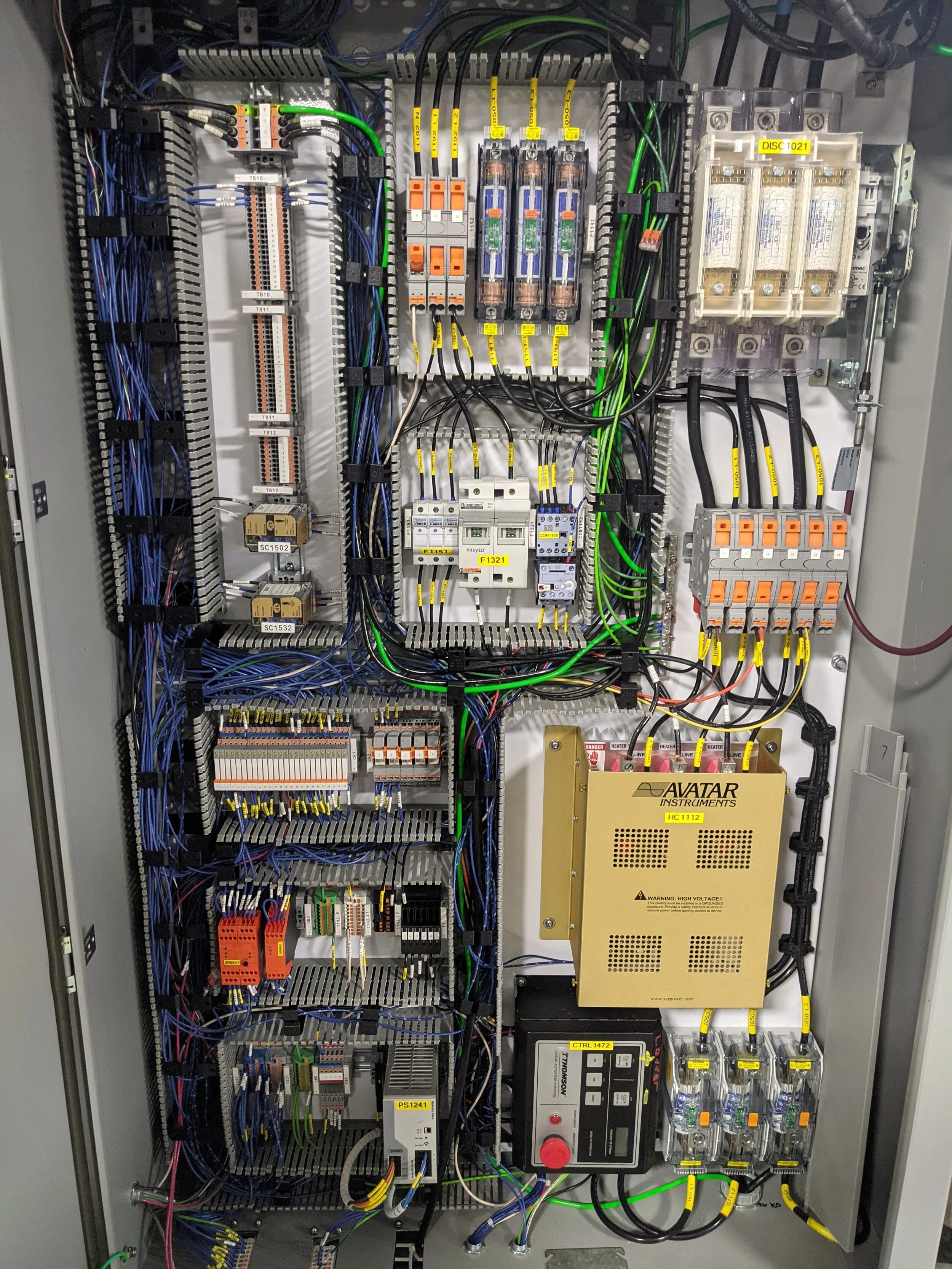

Novum designed, developed, and installed a complete system upgrade including all new electrical enclosures, pneumatic systems, and custom LabVIEW test software.

Built and installed upgraded control and power enclosures in addition to replacing obsolete 75 HP AC drive with new Allen Bradley Power Flex 753 drive

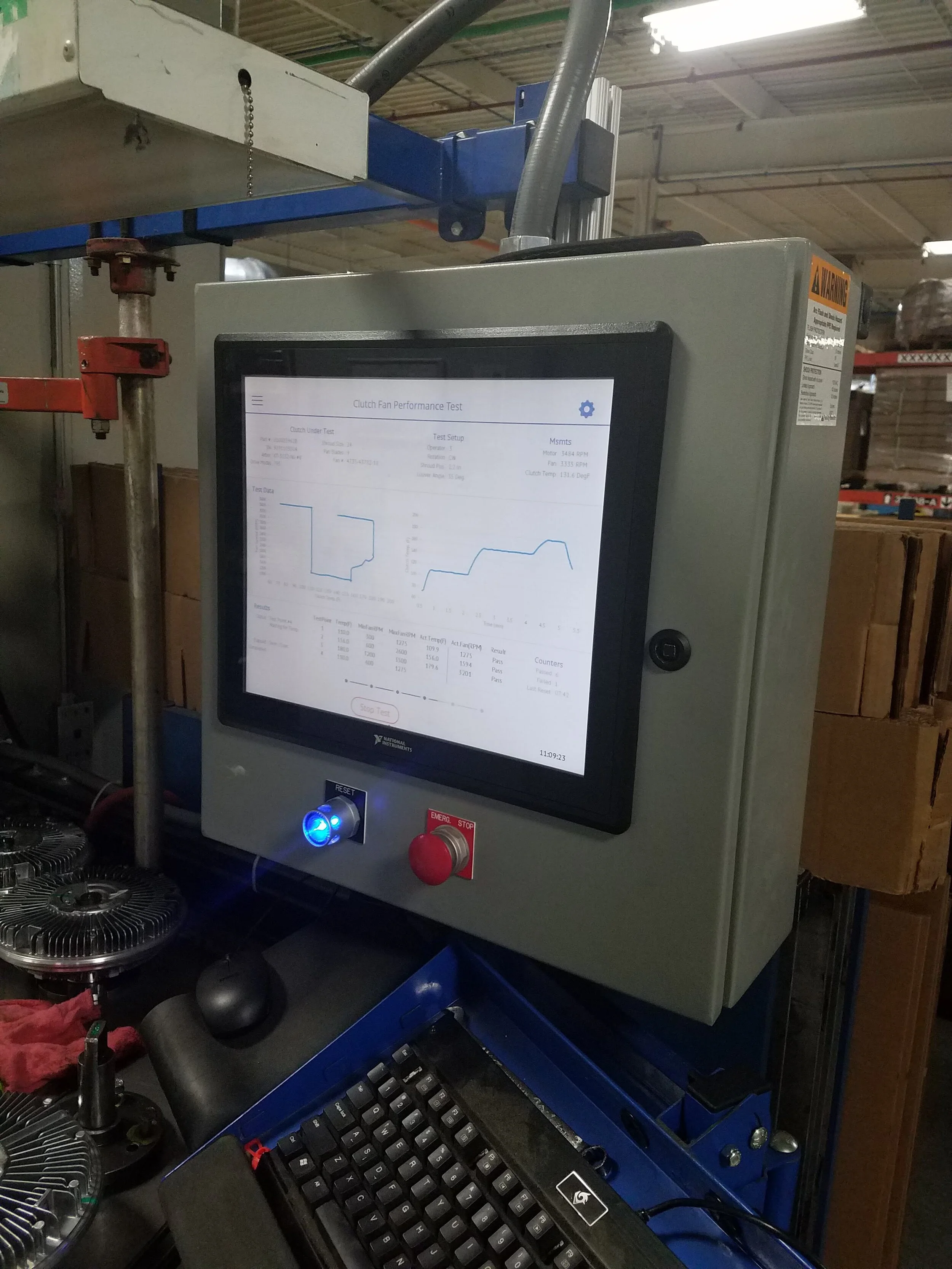

Utilized National Instrument’s Real-Time CompactRIO controller to provide a reliable and future-proof control solution (previous tester used Windows OS platform)

Upgraded controls and software resulted in 25% test time reduction

Custom LabVIEW software based on Object-Oriented Programming to allow for efficient future hardware and OS upgrades