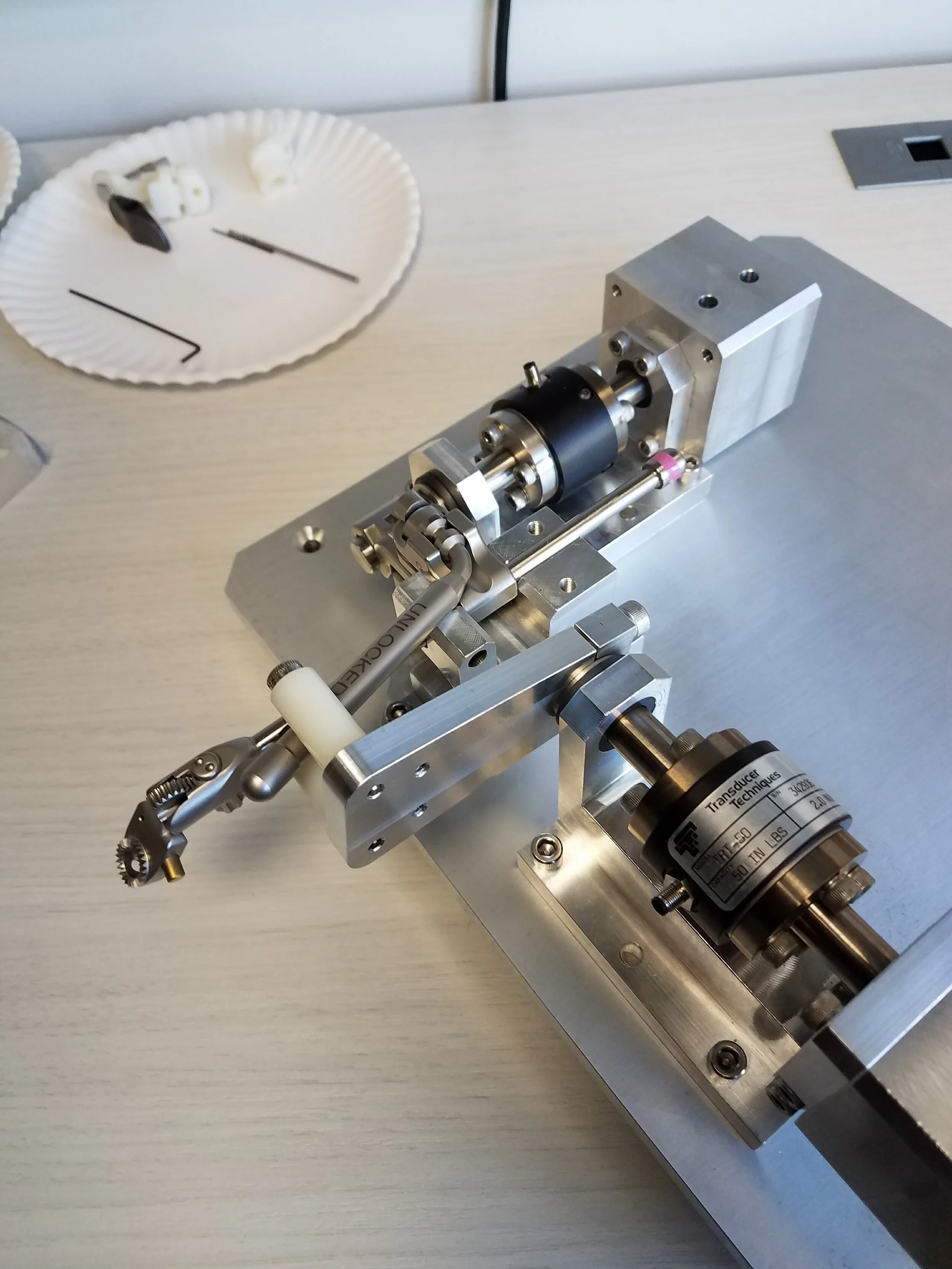

Medical CAM durability test stand

Problem

Durability testing of medical-grade clamps required arduous days of manual operation. Customer needed an automated solution within 2 months.

Solution

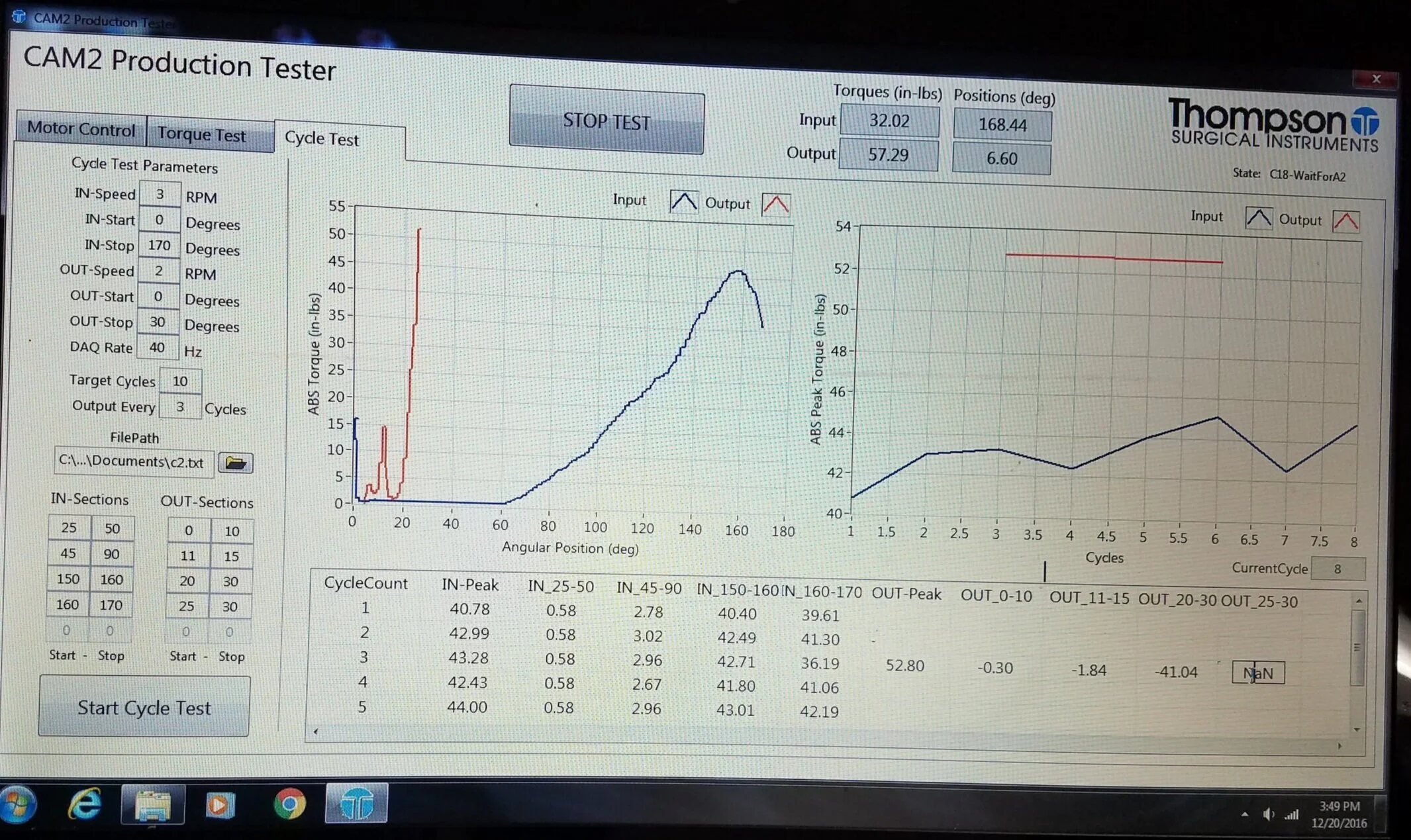

Novum delivered a complete turn-key software package and electrical control panel for automating durability testing. Torque data throughout durability testing was captured and plotted to determine when the “breaking point” of CAM clamp design occurred during durability test.

Developed cost-effective multi-axis test stand for performing durability and calibration tests of medical CAM product

Designed and developed LabVIEW software program to allow for custom test setup, execution, and data logging of performed tests. Utilized multi-process architecture for future scalability of test program functionality.

Built control panel per NFPA 70 & 79 standards

8 week lead time from project initiation to delivery, including testing and on-site fine tuning