High voltage coolant heater inspection

Problem

An automotive manufacturer required a quality inspection end-of-line tester for their high-voltage coolant heater production assembly line. Inspection protocol required over 50 industrial-grade tests to be performed in a matter of minutes to meet throughput demands.

Solution

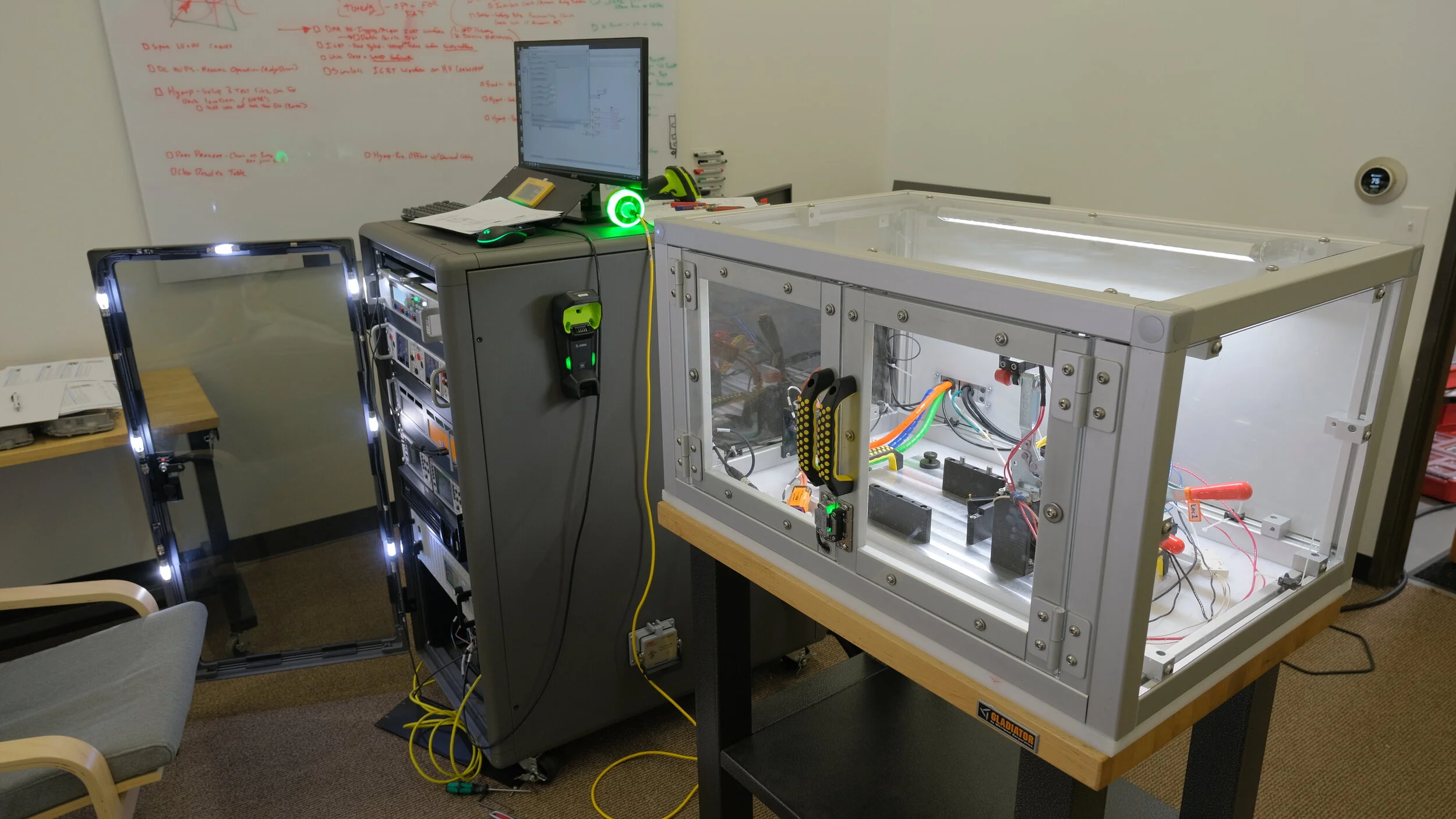

Within a 4 month timeline and an ever-changing scope of work, Novum designed, developed, installed, and commissioned a fully functioning end-of-line quality inspection tester capable of performing 50 tests in 4.5 minutes, offering an 80% improvement from the previous 25 minute cycle time.

Utilized Delacor Queued Message Handler (DQMH) framework to efficiently develop and test software modules for controlling and acquiring data from multiple rack-mounted units

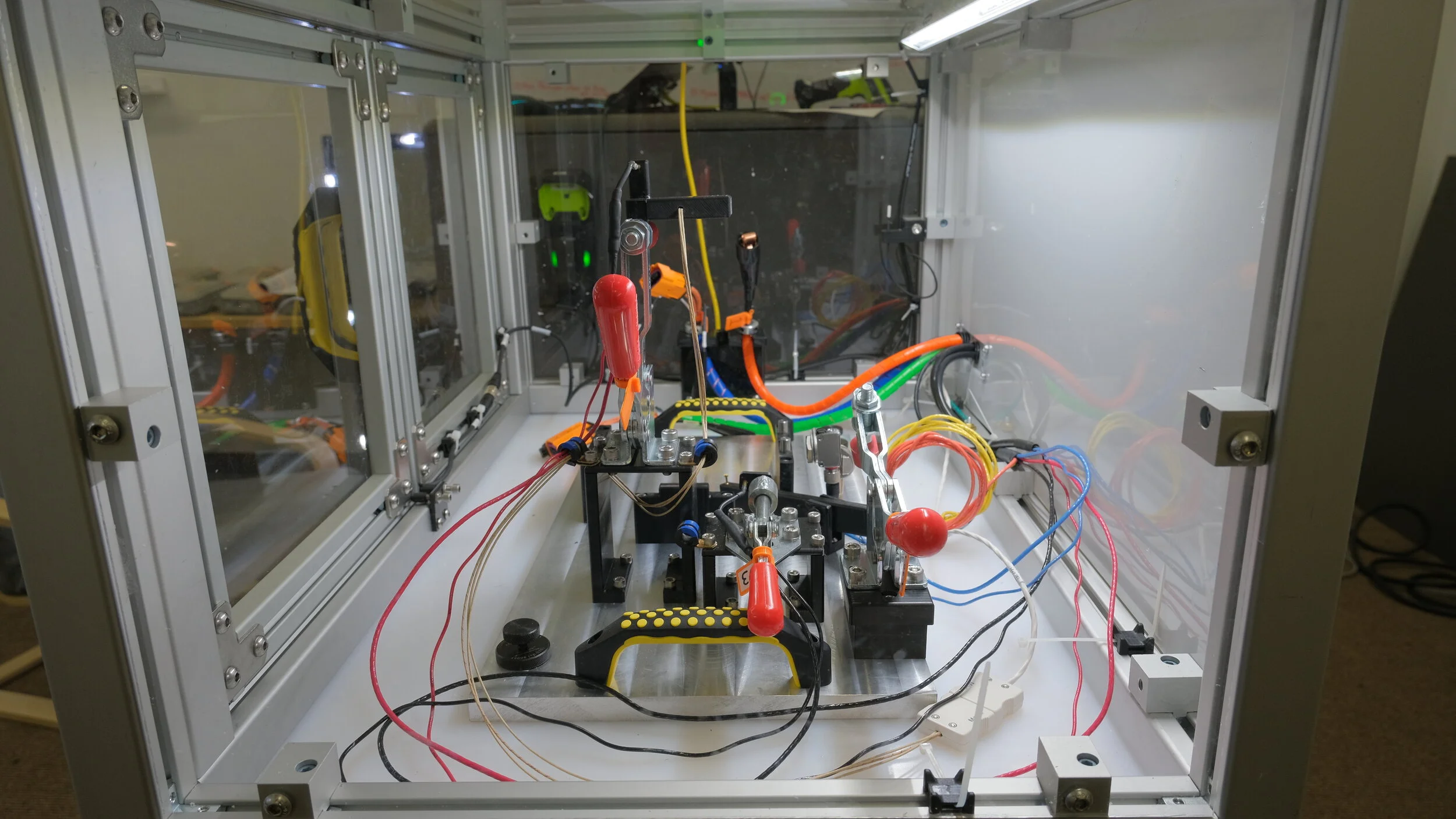

Built custom t-slot aluminum extrusion safety enclosure for performing high-voltage testing

Integrated newly released Banner Engineering multi-color LED work light for providing visual feedback of test status and part status (e.g. red light = failed part)

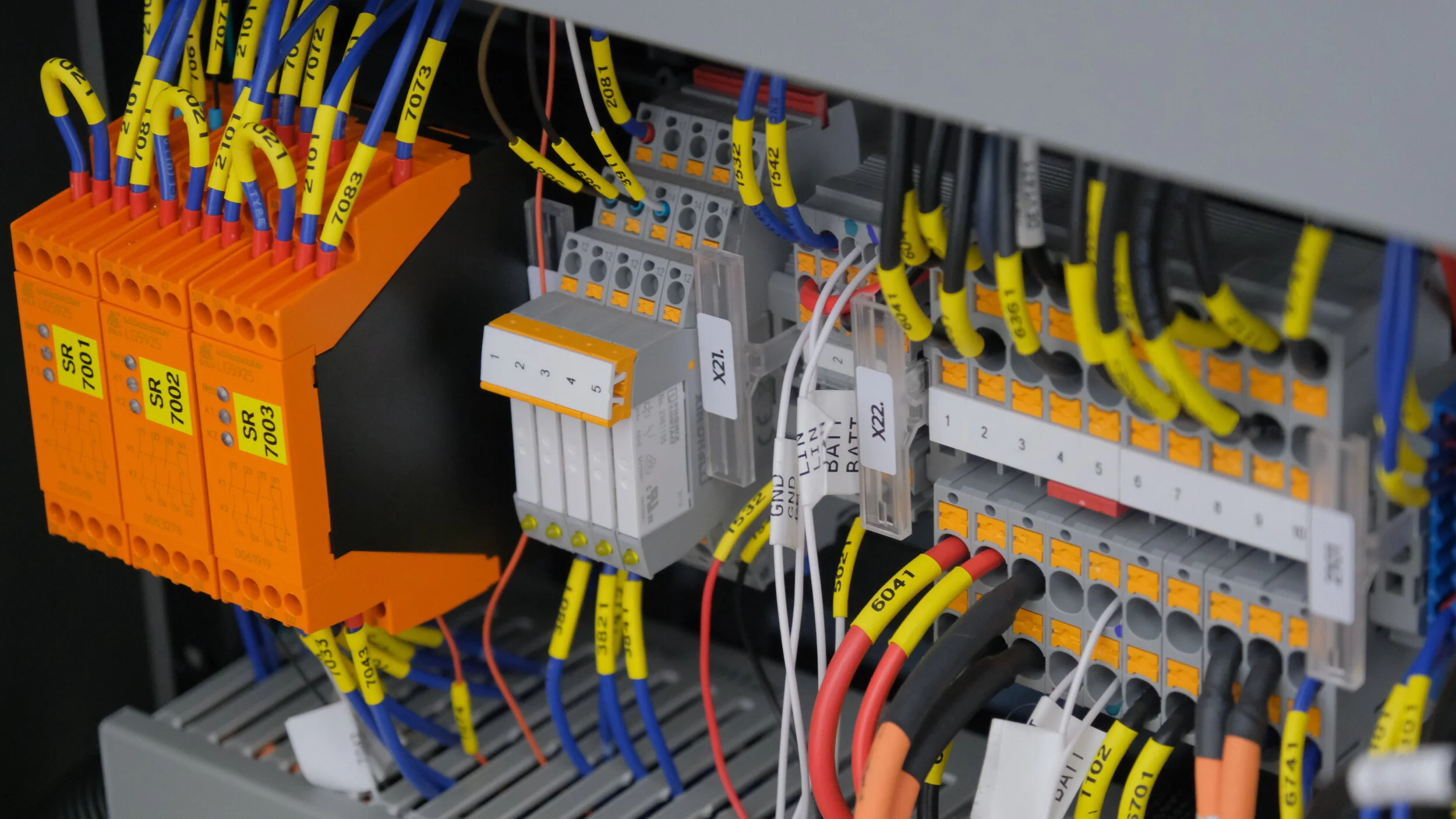

Built electrical panel with Phoenix Contact terminal blocks for safe & secure wiring connections that are vibration-proof and finger-safe

Quality inspection system was developed using multiple industrial-grade rack-mounted units for optimal performance:

Keithly DMM6500 digital multi-meters for capture of PWM curves at 300,000 Hz and feeding data into LabVIEW for analysis

Bender resistance monitoring for insuring safe operation throughout testing duration at high-voltage

National Instruments CompactDAQ hardware platform for providing basis of digital I/O control and analog feedback

Rohde & Schwarz low voltage DC programmable power supply

Elektro-Automatik High-Voltage (500 VDC) DC programmable power supply

On-Logic industrial pc for operating LabVIEW based custom software

Associated Research Hi-Pot & Isolation Resistance tester for testing up to 2,000 VDC

Associated Research Ground Bond tester