Palletizer control system

Problem

A palletizer control system required complete facility removal due to obsolete controls. A new, streamlined control system needed to be designed, built, installed, and commissioned within 4 weeks from project kick-off.

Solution

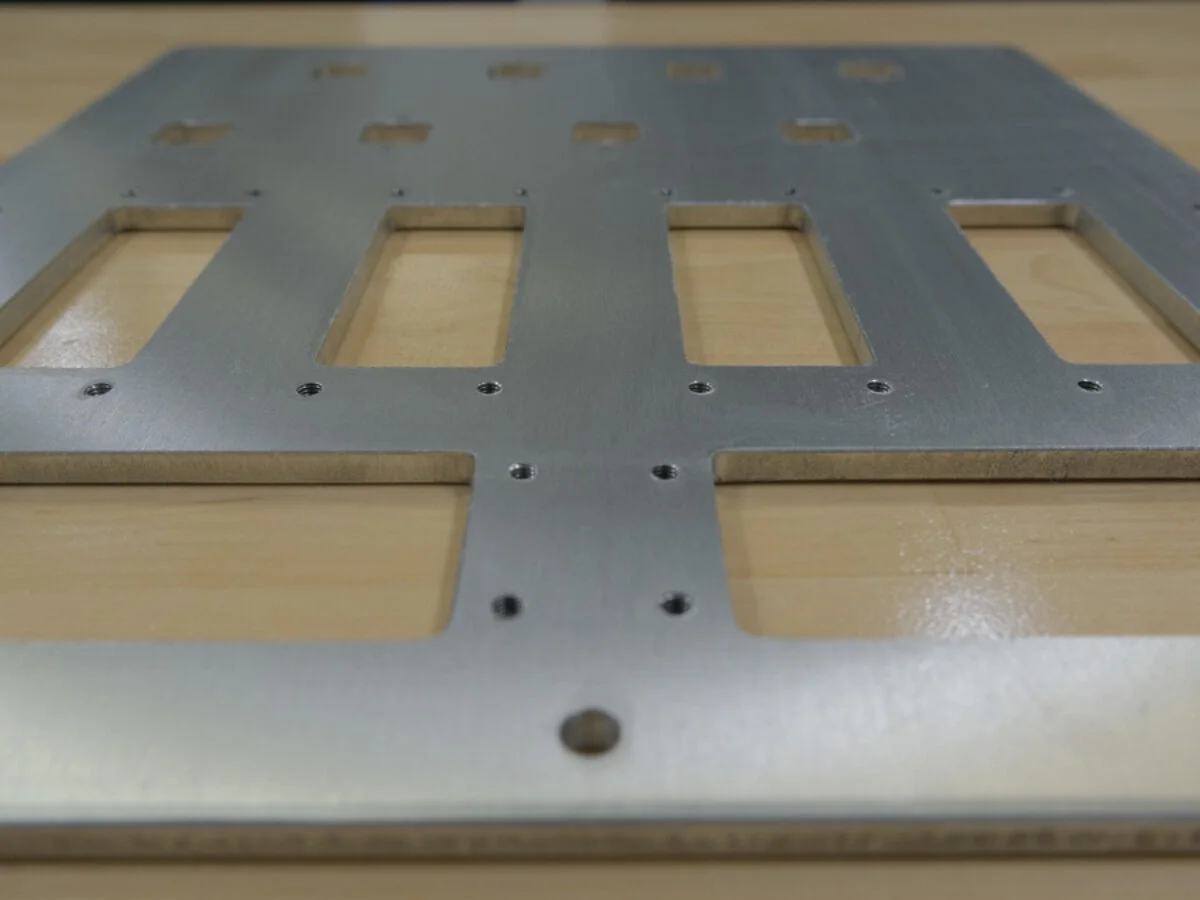

Novum designed, developed, installed, and commissioned a fully-functioning palletizer stand-in control system utilizing the latest scalable, future-proofed PLC control and panel build hardware with thorough documentation for operator usability.

Reduced control system footprint to single-panel floor-mounted disconnect enclosure

Utilized Phoenix Contact I/O blocks for efficient setup and implementation of digital photoeyes with scalability considerations for future-proofing

Integrated Phoenix Contact heavy-duty connectors for efficient cable management and streamlined on-site installation, allowing for quick motor connections and I/O block connections

Selected Allen-Bradley Micrologix 1400 based on customer requirements

Leveraged Automation Direct’s Durapulse GS20 variable frequency drives with Safe Torque Off for improved long-term control, reliability, and safer operation